1. Application in maintenance scenarios

1. Emergency plugging and fault isolation

Scenario: When the valve core is damaged or the seal fails, remove the faulty valve core, seal the valve hole with a plug, and quickly restore the system operation.

Case:

The proportional valve coil of the injection molding machine is burned → temporarily replaced with a plug to ensure normal pressure supply of other oil circuits.

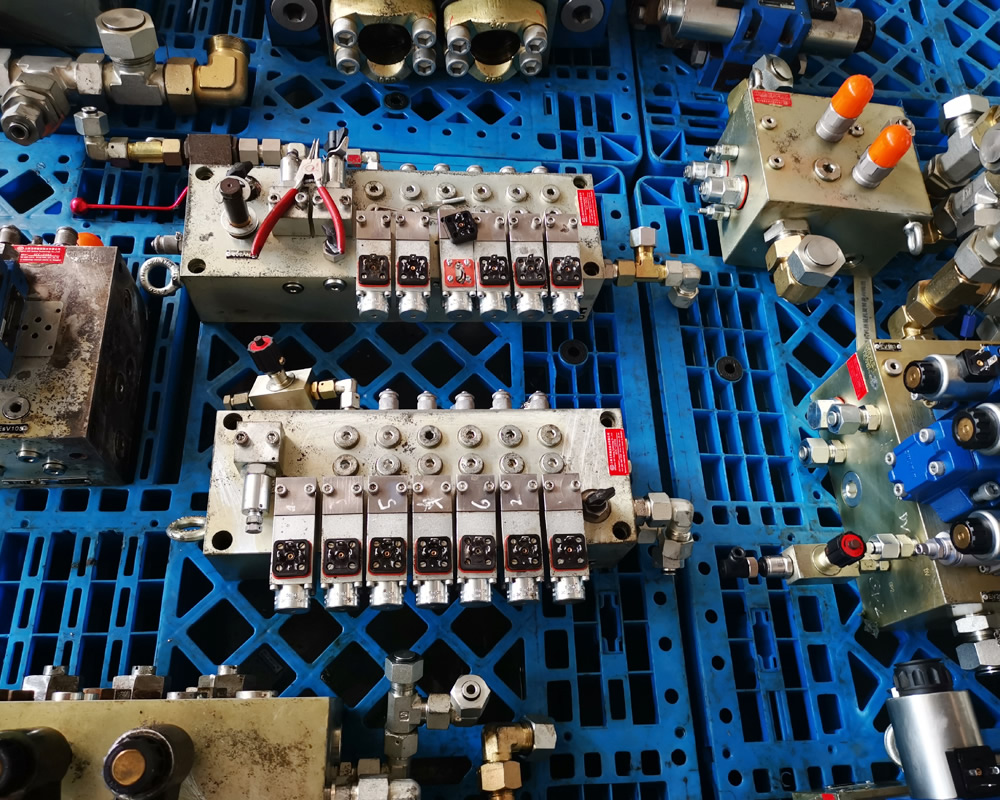

Internal leakage of the multi-way valve plate of the excavator → block the corresponding valve hole and isolate the faulty chamber.

Technical points:

Preferably use O-ring sealing plugs (easy to install and replace within 5 minutes).

When the pressure is greater than 25MPa, a metal cone sealing plug is required (to avoid high-pressure breakdown).

2. Temporary closure of test points

Scenario: After the pressure test is completed after maintenance, the test valve hole is closed.

Operation specification:

Use an external hexagonal pressure test plug (such as HydraForce, SUN series), and no special tools are required for disassembly and assembly.

Apply anti-seizure agent (such as LOCTITE 577) to the threads to prevent thread wear after repeated disassembly and assembly.

2. Application in modification scenarios

1. Reduction of oil circuit functions

Scenario: Simplify the system and close redundant oil circuits.

Case:

The machine tool hydraulic station cancels the workstation fixture function → Use a plug to close the reversing valve hole that controls the fixture.

Engineering machinery removes auxiliary devices (such as hydraulic hammers) → Block the corresponding valve block inlet and outlet oil ports.

Design points:

The plug depth must be ≥1.5 times the thread diameter (to prevent high-pressure oil from shearing the thread).

2. Function upgrade reservation

Scenario: Reserve valve holes for future expansion and temporarily seal them with plugs.

Case:

The press valve block reserves a proportional valve installation position → Pre-install the plug and mark the expansion number (such as "FUTURE V2").